Unveiling the Chemistry of Latex: From Rubber Trees to Everyday Products

Related Articles: Unveiling the Chemistry of Latex: From Rubber Trees to Everyday Products

Introduction

With great pleasure, we will explore the intriguing topic related to Unveiling the Chemistry of Latex: From Rubber Trees to Everyday Products. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Unveiling the Chemistry of Latex: From Rubber Trees to Everyday Products

Latex, a substance synonymous with rubber and elasticity, holds a prominent place in our daily lives. From the familiar comfort of a rubber band to the intricate design of a medical glove, latex products are ubiquitous. But what exactly is latex, and how does this natural substance transform into the versatile materials we encounter?

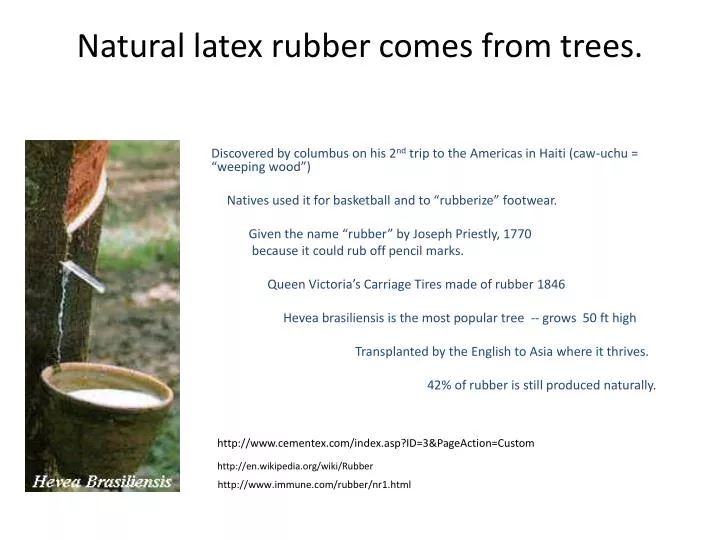

The Natural Source: A Milky Sap

Latex is a milky, sticky fluid found naturally within the vascular system of certain plants, primarily rubber trees (Hevea brasiliensis). This sap, harvested through tapping, serves as a defense mechanism for the tree, protecting it from injuries and infections. It is composed primarily of a complex hydrocarbon polymer called polyisoprene, along with various proteins, resins, and other compounds.

The Transformation: From Sap to Rubber

The raw latex harvested from rubber trees is not directly usable in its natural form. It undergoes a series of processing steps to transform it into the familiar rubber we know.

- Coagulation: This process involves adding an acid, typically acetic acid, to the latex, causing the polyisoprene molecules to clump together, forming a solid mass.

- Washing and Drying: The coagulated latex is then washed to remove impurities and dried, resulting in a rubber sheet.

- Vulcanization: This critical step, discovered by Charles Goodyear in 1839, involves heating the rubber with sulfur. The sulfur atoms create cross-links between the polyisoprene chains, significantly increasing the rubber’s strength, elasticity, and resistance to degradation.

The Versatility of Latex: From Simple to Sophisticated

The processed latex, now a versatile material, finds applications across numerous industries:

- Medical: Latex’s biocompatibility, elasticity, and impermeability make it ideal for medical gloves, catheters, and other medical devices.

- Industrial: Latex is used in the production of conveyor belts, tires, and other durable goods that require strength and flexibility.

- Consumer Products: Latex finds its way into everyday items like rubber bands, balloons, and erasers, providing elasticity and resilience.

- Construction: Latex-based paints and sealants offer durability, water resistance, and flexibility in building applications.

- Clothing: Latex is used in specialized clothing, such as wetsuits, for its water-resistant and insulating properties.

Exploring the Properties of Latex:

The unique properties of latex, stemming from its chemical composition and processing, make it a valuable material:

- Elasticity: Latex’s ability to stretch and return to its original shape is a defining characteristic. This property arises from the long, flexible polyisoprene chains that can easily deform and then recoil.

- Strength: Vulcanization enhances the strength of latex by creating cross-links between the polyisoprene molecules, making it more resistant to tearing and stretching.

- Water Resistance: Latex is naturally water-resistant, making it suitable for applications where impermeability is crucial.

- Biocompatibility: Latex’s non-toxic nature makes it suitable for medical applications where contact with human tissues is required.

Beyond Natural Latex: Synthetic Alternatives

While natural latex holds a prominent position, synthetic latex, derived from petroleum, offers a viable alternative. These synthetic polymers, such as styrene-butadiene rubber (SBR), possess similar properties to natural latex but offer advantages in terms of cost, availability, and consistency.

Addressing Concerns: Allergies and Environmental Impact

Despite its widespread applications, latex has its share of concerns:

- Latex Allergies: A significant portion of the population exhibits allergic reactions to latex proteins, leading to skin irritation, respiratory problems, and even anaphylaxis. This has led to the development of latex-free alternatives in medical and consumer products.

- Environmental Impact: The extraction and processing of natural latex can have environmental consequences, including deforestation, habitat loss, and the use of chemicals. Sustainable practices and responsible sourcing are crucial to mitigate these impacts.

FAQs: Delving Deeper into Latex

Q: What are the different types of latex available?

A: Latex can be broadly classified into natural latex, derived from rubber trees, and synthetic latex, produced from petroleum-based polymers. Natural latex is further categorized based on its source and processing methods.

Q: How is latex processed to make rubber?

A: The transformation of latex into rubber involves several steps: coagulation, washing, drying, and vulcanization. Each step plays a crucial role in shaping the final properties of the rubber.

Q: What are the benefits of using latex in various products?

A: Latex offers several advantages, including its elasticity, strength, water resistance, biocompatibility, and affordability. These properties make it suitable for a wide range of applications.

Q: Are there any risks associated with using latex products?

A: Latex allergies are a significant concern, affecting a considerable portion of the population. The use of latex-free alternatives is essential for individuals with latex sensitivity.

Q: What are the environmental implications of latex production?

A: The extraction and processing of natural latex can have environmental impacts, including deforestation and the use of chemicals. Sustainable practices and responsible sourcing are crucial to minimize these impacts.

Tips: Choosing and Using Latex Products

- Consider Latex Allergies: When purchasing latex products, be aware of potential latex allergies and choose latex-free alternatives if necessary.

- Check for Certifications: Look for certifications such as "Forest Stewardship Council" (FSC) or "Sustainable Forestry Initiative" (SFI) to ensure the latex is sourced from sustainably managed forests.

- Proper Storage: Store latex products in a cool, dry place away from direct sunlight and heat to maintain their quality and prevent degradation.

- Cleaning and Care: Follow the manufacturer’s instructions for cleaning and maintaining latex products to ensure their longevity and performance.

Conclusion: A Versatile Material with Complex Considerations

Latex, a natural substance with a remarkable ability to transform into diverse materials, plays a crucial role in our modern world. Its elasticity, strength, and water resistance make it an invaluable component in medical devices, industrial products, and everyday items. However, the presence of latex allergies and the environmental impact of its production necessitate careful consideration and responsible practices. By understanding the chemistry of latex and its properties, we can appreciate its versatility while mitigating potential risks and ensuring its sustainable use for future generations.

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Chemistry of Latex: From Rubber Trees to Everyday Products. We appreciate your attention to our article. See you in our next article!